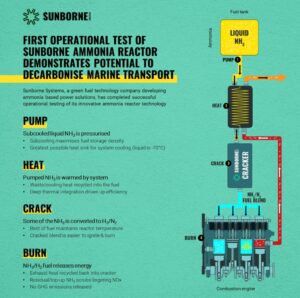

Sunborne Systems & AFC Energy: successful ammonia cracker demonstrations

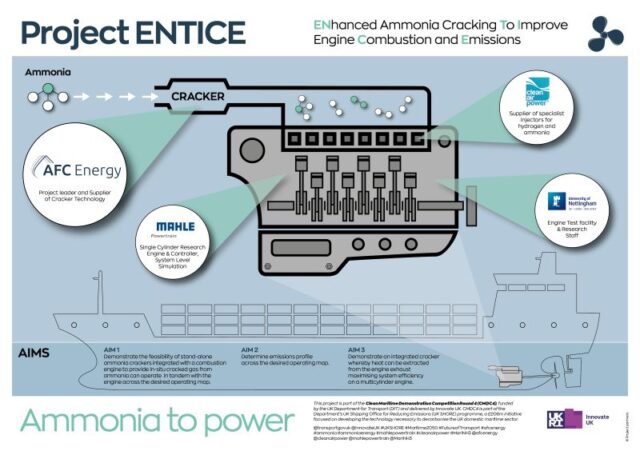

Sunborne Systems ran a successful demonstration for its ammonia cracking reactor in Oxford, producing a fuel blend capable of powering a small vehicle or small generator unit. Also in the UK, AFC Energy announced a similarly successful demonstration of its integrated cracker and purifier system, producing hydrogen fuel which meets purity & ISO standards for heavy vehicle refueling.