Gigawatt-scale electrolyzer manufacturing and deployment

By Trevor Brown on November 14, 2019

ANNUAL REVIEW 2019

Electrolyzers have featured heavily at this year’s Ammonia Energy Conference, which ended today. How much can innovation increase efficiency? How far can volume manufacturing drive down capex? How much could process integration with Haber-Bosch deliver improved ammonia production? How can new, sophisticated strategies optimize variable and baseload power inputs?

These technical questions are all important, but none defines profitability. While progress is being made on all these fronts of research and development, major industrial projects are still moving forward, driving incremental, compounding improvements through the current generation of electrolyzer technologies.

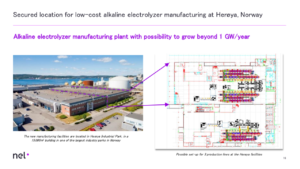

The CEO of Nel Hydrogen, Jon-André Løkke, announced at the Hydrogen Ministerial in Tokyo this September “plans for a GW production facility that will allow renewable hydrogen to become fully competitive with fossil hydrogen.”

A few months earlier, the UK government announced £500,000 financing for ITM Power’s GigaStack project, with partners Ørsted and Element Energy. Like Nel’s proposal, this “aims to dramatically reduce the cost of electrolytic hydrogen,” by achieving economies of scale through volume manufacturing: again, a gigawatt-scale production factory.

(To clarify a common question, a “gigawatt-scale” electrolyzer factory is not a factory that makes GW-scale electrolyzers. Instead, it is a factory that makes many smaller electrolyzers, and its annual output would have a combined power rating of one GW).

And last month, Siemens announced its “Murchison Renewable Hydrogen Project – a large scale (up to 5,000 MW) combined solar and wind farm to produce low-cost renewable hydrogen.” In the last year, we have moved from 100 MW projects to 1 GW projects. An order of magnitude change.

“This project will not only help local industry but also the growing demand for green hydrogen from Asian and other markets,” said [Executive Chairman of Hydrogen Renewables Australia, Terry] Kallis. “Imagine exporting West Australian sunshine and wind to the world in the form of hydrogen.”

Siemens announcement, New Renewable Hydrogen Project at Australia’s Best Combined Solar and Wind Site Announced, October 8, 2019

The Murchison Renewable Hydrogen Project is proposed to be developed in stages:

– A demonstration phase providing hydrogen for transport fuels

– An expansion to blend with natural gas in the nearby Dampier to Bunbury pipeline.

– A large expansion to produce hydrogen for the Asian markets, notably Japan and Korea.

As I understand it, the hydrogen carrier that enables this 5 GW of renewable energy export, in phase three, has not yet been chosen but ammonia is high on the list.

AMMONIA ENERGY REPORTING ON THIS TOPIC SINCE LAST YEAR

- October 2019: Green Ammonia Plants in Chile, Australia, New Zealand

- October 2019: Israeli Group Develops New Electrolysis Technology

- August 2019: Yara and Nel collaborate to reduce electrolyzer costs; announce green ammonia pilot in Norway by 2022

A YEAR IN REVIEW

This article is part of our Annual Review 2019. To mark the third anniversary of Ammonia Energy, we are highlighting ten “tip-of-the-iceberg” topics that we’ve written about over the last 12 months. In each case, we think we see something just peeking above the current flow of events that is developing into a major phenomenon below the surface.

Read all the stories in our Annual Review 2019.