Low-carbon ammonia synthesis: Japan’s ‘Energy Carriers’

By Trevor Brown on November 11, 2016

In 2018, a pilot plant in Japan will demonstrate a new way to produce ammonia at industrial-scale, with a low carbon footprint.

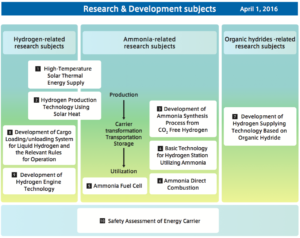

This is part of Japan’s ‘Energy Carriers’ R&D initiative, which aims to develop technologies to enable the nation’s transition to a carbon-free hydrogen economy.

The scope of the program covers ten subjects that encompass the full “CO2-free hydrogen value chain.” Three of these ten programs describe a technology pathway for making low-carbon ammonia, which can be used for energy storage and distribution.

Their aims are to:

- develop a high-temperature solar thermal energy supply;

- produce hydrogen from the solar heat, using either a Membrane Iodine-Sulfur Process or a new Steam Electrolysis system;

- develop a more efficient, low-temperature ammonia synthesis process using this CO2-free hydrogen.

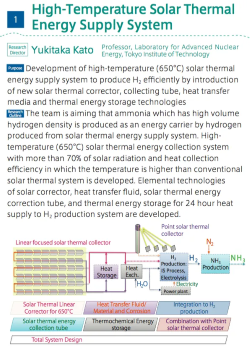

Research Director Yukitaka Kato, from the Tokyo Institute of Technology, leads the program to develop an improved solar thermal energy supply.

This project aims to develop a solar power generation system that runs at higher than normal temperatures (650°C). The system is designed to achieve “more than 70% of solar radiation and heat collection efficiency,” by using a “new solar thermal corrector, collecting tube, heat transfer media and thermal energy storage technologies.”

The purpose of this efficient solar technology is to generate carbon-free heat and power for hydrogen production.

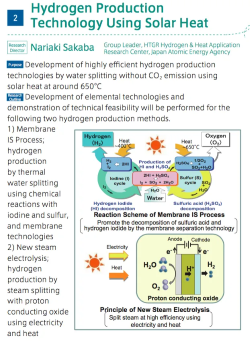

Nariaki Sakaba, from the Japan Atomic Energy Agency, is the Research Director of the program for “highly efficient hydrogen production technologies by water splitting.”

This area of the project aims to develop two separate technologies, and demonstrate the technical feasibility of both.

The first is a Membrane IS Process, which harnesses two reaction cycles: Iodine (hydrogen iodide, HI) and Sulfur (sulfuric acid, H2SO4). Hydrogen, from a water feedstock, is generated by cycling through the decomposition reactions of these two chemicals, using membrane separation technology.

The second is a new electrolysis technology, which aims to “split steam at high efficiency using electricity and heat,” by means of a proton conducting oxide.

Both these technologies require not just power but also heat – and it is the full utilization of both solar power and solar heat that drive the efficiencies of this system.

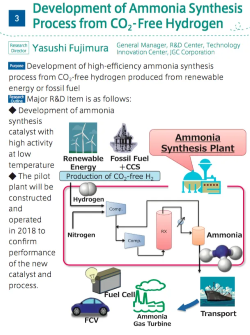

The ammonia synthesis process under development does not require so much heat – in fact, it is designed to operate at low temperature.

The standard ammonia production process, Haber-Bosch, operates at high pressures and high temperatures, between 400 and 500°C. So, by developing an “ammonia synthesis catalyst with high activity at low temperature,” these researchers hope to improve the system’s efficiency by reducing the amount of heat energy it requires – of course, by using a carbon-free hydrogen feedstock, they also eliminate the need for any fossil fuel feedstock.

(By contrast, the new technologies being developed in the US, with funding from ARPA-E, focus on reducing their energy requirements by operating at low pressure, instead of low temperature – while also aiming to avoid the use of fossil fuels.)

The ammonia synthesis pilot plant, which will be built and operated in 2018, should “confirm performance of the new catalyst and process.”

I wrote more generally about Japan’s ‘Energy Carriers’ program last week, in an article that addressed how to create a market for low-carbon ammonia: product labeling. The price premium available to ammonia merchants selling into the low-carbon energy market can only be realized when producers begin to calculate and communicate the carbon footprint of their product.

To understand the motivation and impressive pace of development of the Japanese ‘Energy Carriers’ project, it is important to recognize the commercial advantage of being the first-mover in developing low-carbon technologies. (This is, perhaps, an especially important point to make, given this week’s election of the future President Trump and his potential impact on clean energy research, development, and deployment in the US.)

Reducing CO2 emission is a global issue. For Japan, a country poor in energy resources, it is necessary to construct a low-carbon society as well as to promote a stable energy supply … The research, development and demonstration of hydrogen technologies with industry-academia-government collaboration under the leadership of government will contribute significantly to solve energy and environment problems in Japan. And it will eventually bring Japan a world leader in hydrogen utilization and the related industries …

‘Energy carriers’ is the method to efficiently store and transport hydrogen as liquid, while hydrogen, gaseous at normal state, is difficult to handle.

We aim to build CO2-free hydrogen value chain by focusing on the developments of technologies for CO2-free hydrogen production, conversion to energy carriers; liquid hydrogen, organic hydride and ammonia, and storage, transportation and utilization.

Japan’s SIP ‘Energy Carriers‘

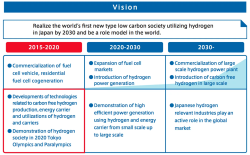

The vision of the ‘Energy Carriers’ program focuses on the nation’s economic opportunity. This “industry-academia-government collaboration,” will develop significant intellectual property and corporate know-how, between 2020 and 2030, when it scales up from demonstration to large-scale deployment.

The ‘Energy Carriers’ program is not some decades-long R&D project without near-term prospects for commercialization. It is specifically designed to accelerate technologies into deployment, creating a competitive advantage for its national industries in a changing global energy economy. Providing national energy security by establishing “the world’s first new type low carbon society utilizing hydrogen,” is only the first step. The real opportunity comes after this R&D program makes “Japan a world leader in hydrogen utilization and the related industries,” when the commercial exploitation of these technologies will allow “Japanese hydrogen relevant industries [to] play an active role in the global market.”

While the profit opportunity for the displacement of fossil fuels in the Japanese market is certainly large, the addressable global market – into which Japan will then export its technologies and expertise – will be vast.

The Research Director leading the development of this new ammonia synthesis process, Yasushi Fujimura, is the General Manager of R&D at the Technology Innovation Center of JGC Corporation.

JGC is a global engineering and construction firm, focused on oil and gas production, refineries, and LNG – but it has a growth strategy that sees significant diversification away from fossil energy in the future.

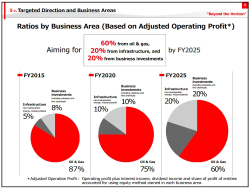

JGC published its “Growth Strategy for Realization of Corporate Vision,” Beyond The Horizon, in May 2016. According to this, by 2025, JGC aims to have reduced drastically its reliance on the oil and gas sector: from 87% down to 60% of operating profit. The new profit drivers, each targeted to generate 20% of profits, will be Infrastructure, including “non-hydrocarbon energy,” and Business Investments, “including catalysts” and – presumably – its new ammonia synthesis technologies.

Originally published at our sister publication, Ammonia Industry: Low-carbon ammonia synthesis: Japan’s ‘Energy Carriers’ R&D.