Overcoming the Selectivity Challenge in Electrochemical Ammonia Synthesis

By Trevor Brown on October 06, 2017

Ammonia Energy Anniversary Issue: a “top five” development in technology advancement

In the last 12 months …

The research community has made great progress toward solving the “selectivity challenge” in electrochemical ammonia synthesis. Although, rather than an actual solution, mostly what we have is a range of sophisticated work-arounds that succeed in making this problem moot.

Over, around, and away from the Selectivity Challenge

Last year, the US Department of Energy hosted a roundtable discussion on sustainable ammonia. The “grand challenge,” it concluded, was that “currently there is no viable … active, selective, scalable, long-lived catalyst.” Certainly, one of the main hurdles for electrochemical technologies, for decades, has been this challenge of selectivity.

Put simply, the selectivity challenge is that catalysts prefer to make hydrogen instead of ammonia – even those that are really good at making ammonia are even better at making hydrogen. So, in electrochemical ammonia synthesis technologies thus far, most of the energy was wasted making hydrogen instead of making ammonia.

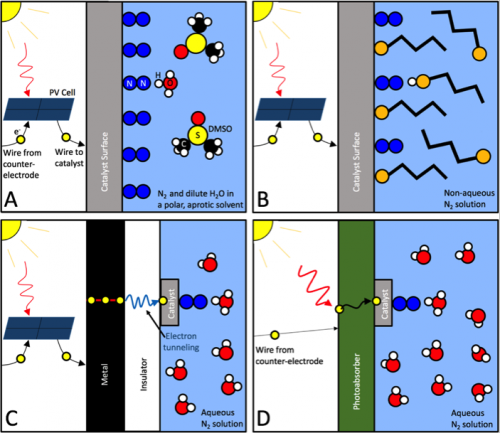

The dream of electrochemical ammonia synthesis is that we could have a box, fed with just electricity, water, and air, and – with the ideal catalyst inside – it would churn out ammonia. At the 2016 NH3 Fuel Conference, some veteran investigators despaired that it would ever be possible to find a catalyst that could overcome this hurdle. But, in a way, that has led to a revival for an old-school technology: the electrolyzer.

By plugging an electrolyzer into a traditional Haber-Bosch loop you can produce ammonia from renewable power, without the need for any new catalyst development: you have simply separated one electrochemical reaction into two steps. The feasibility of this has led to immediate plans for deployment of pilot plants and demonstrations, in the U.K., Australia, and the Netherlands, and has brought new champions to the arena, like the International Energy Agency. The notion of using electrolyzers might seem obvious but, with high hopes for breakthroughs in direct electrochemical technologies, nobody was investing in demonstration projects.

Nonetheless, direct electrochemical technologies have also found other ways around the selectivity problem.

This year, a major ongoing research collaboration, led by Stanford University and the Technical University of Denmark, developed a technology that splits the reaction into three stages, in a complex but efficient lithium-cycling process. “While we have depicted a step-wise reaction scheme … a continuous process in a compartmentalized device would be beneficial for implementation.”

And in South Korea researchers stepped away from initial solid-state technologies, moved past molten salt electrolytes, and landed upon a liquid-state technology that they believe will vastly increase selectivity for ammonia. If they can hit their lab-scale production target for 2019, it will be ten thousand times better than their 2012 results and the closest an electrochemical ammonia synthesis technology has come to being commercially competitive.

Ammonia Energy reporting

- July 2017: Sustainable ammonia synthesis: SUNCAT’s lithium-cycling strategy

- June 2017: Electrochemical ammonia synthesis in South Korea

- June 2017: The International Energy Agency’s scenarios for renewable ammonia

- June 2017: Renewable Ammonia cost-competitive with Natural Gas Ammonia

- May 2017: Power to Ammonia: alternative synthesis technologies

- December 2016: Grand Challenges in Sustainable Ammonia Synthesis – DOE Roundtable Report, 2016

A year in review

To mark the first anniversary of Ammonia Energy, we reviewed the most important developments from the last 12 months. This “top ten” list spans two areas: five are technology advances that will arguably produce the most important opportunities for ammonia energy, and five are economic implementation steps that are arguably the most significant moves toward real-world deployment.

Technology advancement:

- The Dawn of Bio-Ammonia

- Advances in Ammonia-Fired Gas Turbines Open Up Major Use Case

- Overcoming the Selectivity Challenge in Electrochemical Ammonia Synthesis

- Progress toward Ammonia-to-Hydrogen Conversion at H2 Fueling Stations

- Development of Direct Ammonia Fuel Cells

Economic implementation:

- Yara’s Solar Ammonia Plant is a Key Step toward Global Trade in Renewable Energy

- Power-to-Ammonia: the Economic Viability of Ammonia Energy

- Green Ammonia Consortium: Bright Prospects in Japan for Ammonia as an Energy Carrier

- The Maritime Industry Begins Assessment of Ammonia as a Fuel

- Ammonia Energy Gains Recognition from U.S. Department of Energy