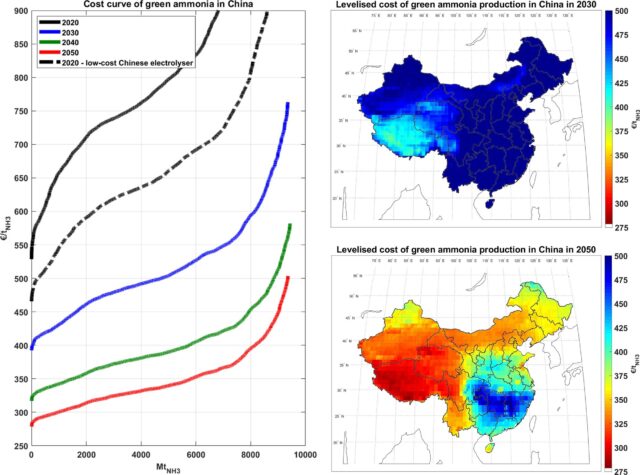

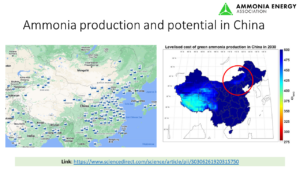

Renewable ammonia in China: full speed ahead

China is keeping pace with IEA predictions for electrolyzer installations, with as much as 55% of the world’s total capacity to be installed there by 2028. Coupled with strong wind-power resources, domestic manufacturing capabilities and multiple economic drivers to transition away from coal-based ammonia production, China is ideally positioned to speed up the deployment of renewable ammonia projects.