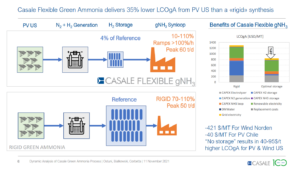

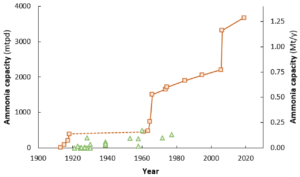

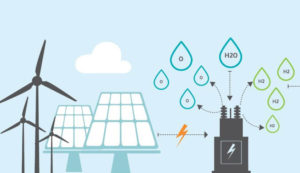

To design, build & operate a hydroelectric ammonia production plant fed by electrolytic hydrogen, what considerations need to be taken into account? Our recent episode of Ammonia Project Features explored this question, focusing on an upcoming project being developed in Paraguay by ATOME, URBAS and Casale. The use of surplus hydropower, existing industrial infrastructure, proactive engineering and commercially-available, flexible ammonia synthesis technologies all adds up to a less challenging task for developers, and a potential project template going forward.