An NYK-led consortium, which includes Japan Engine Corporation, IHI Power Systems and Nihon Shipyard, has announced that a construction contract has been signed with Japan Marine United to build its 40,000 m3 ammonia-fueled medium gas carrier (AFMGC) in Ariake. The vessel is due to be delivered in November 2026.

Content Related to Japan Engine Corporation

NYK's ammonia-powered gas carrier to hit the water in late 2026

Maritime updates: modeling engine room fuel leaks, testing a new fuel supply system

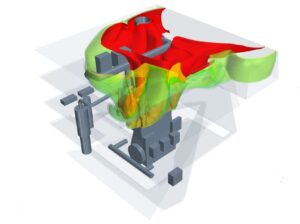

ABS has used computational fluid dynamics to model ammonia dispersion patterns in a ship’s engine room, with the aim of producing a fast, real-time response system for ammonia leaks. In Japan, a fuel supply system for large-scale, low-speed, two-stroke marine engines is undergoing final verification testing. Mitsubishi Shipbuilding aims to become a key technology provider of such systems, and in the ammonia maritime fuel space.

IHI, NYK Line report successful marine engine testing in Japan

Successful testing has been completed at IHI’s facilities in Ota, Japan. A four-stroke marine engine - fully integrated with exhaust gas aftertreatment and fuel supply systems - produced stable operations running on up to 80% ammonia fuel. Emissions of dinitrogen monoxide (N2O) and ammonia slip were reported as “virtually zero”.

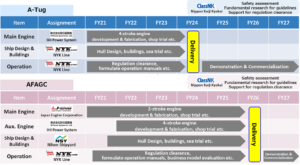

Wärtsilä & Møkster join forces, Japanese maritime consortium takes next steps

Wärtsilä and Simon Møkster Shipping will explore the feasibility of using ammonia as the main fuel in dual fuel engines. Currently Møkster's fleet operates on LNG. In Japan, NYK Line, Japan Engine Corporation, IHI Power Systems, Nihon Shipyards and ClassNK will all collaborate on a demonstration project of ammonia-powered vessels in Japan. First announced in 2020 with three vessel concepts, two of the three vessel designs now have a commercialisation schedule fully defined (the A Tug and the AFAGC).

The maritime sector's ammonia learning curve: moving from scenario analysis to product development

ANNUAL REVIEW 2019: The maritime industry is learning about ammonia fast. It is searching for a new bunker fuel, and ammonia is one of the few options that can realistically deliver a 50% reduction in the sector's GHG emissions by 2050. The IMO declared this target in April 2018 and, in last year's Annual Review, I wrote about all the reports that were published demonstrating that ammonia could deliver this outcome. In the last 12 months, by contrast, we have moved quickly beyond analysis and into engineering design, technology testing, and product development.