This session of our 2023 annual conference explored the need for high quality data as an input to ammonia certification. The panel featured Jennifer Beach (Starfire Energy), Lara Owens (MiQ), Jim Seely (Authentix), Selim Sevikel (Global CCS Institute), and Rajiv Sabharwal (Bureau Veritas).

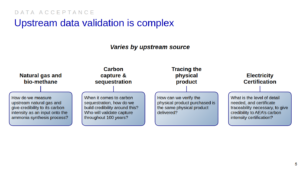

This issue is a key focus for the AEA, as our under-development ammonia certification system will require auditable data from a host of stakeholders – including gas and electricity suppliers, CO2 offtakers, and others – in order to calculate a true and trustworthy carbon footprint.