Chinese automotive manufacturer GAC Group has unveiled its first ammonia-powered, 120 kW engine for passenger cars at a recent showcase event in Guangzhou.

China

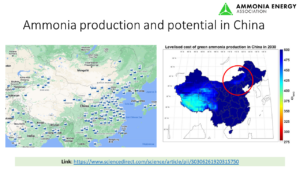

China: scaling-up “flexible” ammonia production powered by renewable energy

The cost gap between fossil-based ammonia production and electrolysis-based ammonia production in China is arguably the smallest in the world. In our May episode of Ammonia Project Features, we explored two new, “flexible” renewable ammonia projects being developed in northeast China, as well as some of the engineering challenges as we scale-up electrolysis plants to gigawatt-sized.

First ammonia-ready containerships delivered

Two ammonia-ready vessels - the CMA CGM Masai Mara and the ALS Ceres - were delivered this May. Both are the first in a series of six containerships contracted to be built at different Chinese shipyards.

Cracking-based propulsion systems, new vessels on order

Norwegian technology developer Pherousa announced that it has developed & validated an ammonia cracking-based propulsion system, with plans to order six Ultramax vessels fitted with the technology. Grieg Maritime has ordered up to four ammonia-ready bulk carriers from China State Shipbuilding Corporation for delivery in 2026. And a new container ship design has been unveiled by the Mærsk Mc-Kinney Møller Center for Zero Carbon Shipping.

Scaling flexible ammonia production in China

Explore two flexible renewable ammonia production projects in China: Topsoe's in Baotou, and Envision Energy's in Chifeng City. We also welcome the Institute for Sustainable Process Technology to discuss the scale-up of electrolyzer plants to the GW-scale.

China Energy: foreign investments in ammonia

State-owned enterprise China Energy has announced new ammonia initiatives in three countries, with a reported budget of $20 billion to invest outside China over the next few years. A partnership with Petrobras in Brazil, construction of a new renewable ammonia mega-project in Morocco, and a construction start date for a renewable ammonia plant next to the Suez Canal in Egypt have all been announced in the last few weeks.

New electrolysis-based ammonia projects in China

Jilin Electric Power Company has selected LONGi Hydrogen and SANY Hydrogen as electrolyser technology providers for a 180,000 tonnes per year renewable ammonia project in Da’an, northeast China. A growing list of renewable ammonia projects is being developed in the country, with many focused on decarbonised production of chemicals.