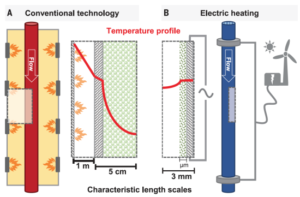

A May 2019 paper published in Science reports on a technological advance that may have significant implications for ammonia production. The paper, Electrified methane reforming: A compact approach to greener industrial hydrogen production, presents a method for providing the heat required for steam methane reforming from renewable electricity instead of natural gas. The carbon intensity of ammonia production could thereby be reduced by about 30%. And, last month, Haldor Topsøe announced that it plans to build a demonstration plant in Denmark that will produce “CO2-neutral methanol from biogas using eSMR technology.” The plant is expected to be “fully operational in the beginning of 2022.”

Denmark

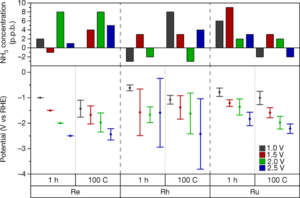

A rigorous protocol for measuring electrochemical ammonia synthesis rates

NEWS BRIEF: A paper published this week in Nature addresses the challenge of accurately reporting synthesis rates for electrochemical ammonia production technologies. According to the authors, from Stanford University, the Technical University of Denmark (DTU), and Imperial College London, it is not always clear if new technologies really synthesize ammonia, or if the researchers simply measured contaminants. This is because, at experimental scale, materially significant amounts of ammonia (or other nitrogen-containing molecules) could be present in the air, membranes, catalysts, or simply the researchers' breath. To support the development of viable electrochemical ammonia synthesis technologies, the authors propose "benchmarking protocols," and "a standardized set of control experiments."

Green ammonia: Haldor Topsoe's solid oxide electrolyzer

Haldor Topsoe has greatly improved the near-term prospects for green ammonia by announcing a demonstration of its next-generation ammonia synthesis plant. This new technology uses a solid oxide electrolysis cell to make synthesis gas (hydrogen and nitrogen), which feeds Haldor Topsoe's existing technology: the Haber-Bosch plant. The product is ammonia, made from air, water, and renewable electricity. The "SOC4NH3" project was recently awarded funds from the Danish Energy Agency, allowing Haldor Topsoe to demonstrate the system with its academic partners, and to deliver a feasibility study for a small industrial-scale green ammonia pilot plant, which it hopes to build by 2025. There are two dimensions to this technology that make it so important: its credibility and its efficiency.

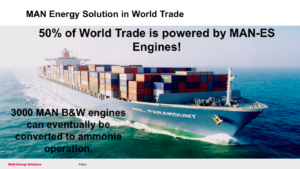

MAN Energy Solutions: an ammonia engine for the maritime sector

In June 2018, MAN Diesel & Turbo rebranded itself MAN Energy Solutions, reflecting the maritime engine market leader's "strategic and technological transformation" towards sustainability. The company was "taking a stand for the Paris Climate Agreement and the global pursuit of a carbon-neutral economy." According to Uwe Lauber, Chairman of the Board, "our activities have a significant impact on the global economy. In shipping, for example, we move more than half of the global stream of goods ... [and] the path to decarbonising the maritime economy starts with fuel decarbonisation, especially in container shipping." This week, the company took a significant step towards realizing its vision, disclosing that it is "pressing ahead with developing ... an ammonia-fuelled engine." This builds on the technology development pathway that MAN ES presented at the NH3 Energy+ Topical Conference at Pittsburgh in October 2018. The budget and timeline are set: the €5 million (USD$5.7 million) project will last two to three years and, if the shipowners decide to deploy the finished product, "the first ammonia engine could then be in operation by early 2022."

Siemens Gamesa investigating green ammonia pilot plant in Denmark

Another week, another green ammonia pilot plant. Siemens Gamesa, the world's largest wind turbine manufacturer (by installed capacity), has announced a partnership with local climate innovation fund Energifonden Skive to investigate the production of ammonia from wind power at an eco-industrial hub in Denmark's "Green Tech Valley." The announcement describes "an agreement to jointly explore eco-friendly ammonia production as a way to store surplus electricity from wind turbines. The goal: a pilot plant at GreenLab Skive."

NH3 Energy+ Topical Conference schedule published

This week, the NH3 Fuel Association published the full technical schedule for the NH3 Energy+ Topical Conference, which will be hosted within the AIChE Annual Meeting, on October 31, 2018, in Pittsburgh, PA. Featuring more than 50 oral presentations, this year's event will be our busiest yet. Speakers and co-authors from 16 countries, and 18 states across the USA, will present research and development from 68 separate companies and research institutions. Registration for the AIChE Annual Meeting is now open, with reduced rates until September 17. Full details are at the NH3 Fuel Association website.

All together now: every major ammonia technology licensor is working on renewable ammonia

The second annual Power to Ammonia conference, which took place earlier this month in Rotterdam, was a tremendous success. It was again hosted by Proton Ventures, the Dutch engineering firm and mini-ammonia-plant pioneer, and had roughly twice as many attendees as last year with the same extremely high quality of presentations (it is always an honor for me to speak alongside the technical wizards and economic innovators who represent the world of ammonia energy). However, for me, the most exciting part of this year's event was the fact that, for the first time at an ammonia energy conference, all four of the major ammonia technology licensors were represented. With Casale, Haldor Topsoe, ThyssenKrupp, and KBR all developing designs for integration of their ammonia synthesis technologies with renewable powered electrolyzers, green ammonia is now clearly established as a commercial prospect.

Ammonia Tagged as Storage Medium for Wind Energy

Henrik Stiesdal is a distinguished figure in the field of wind energy. As such, he has had ample occasion to contemplate the field’s challenges and opportunities. Recently he concluded that ammonia may become an important part of wind energy’s future.

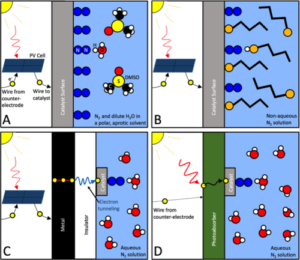

Overcoming the Selectivity Challenge in Electrochemical Ammonia Synthesis

In the last 12 months ... The research community has made great progress toward solving the "selectivity challenge" in electrochemical ammonia synthesis. Although, rather than an actual solution, mostly what we have is a range of sophisticated work-arounds that succeed in making this problem moot.