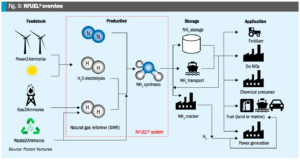

The movement toward small-scale ammonia is accelerating for two reasons. First, small ammonia plants are flexible. And, second, small ammonia plants are flexible.

They are feedstock-flexible, meaning that they can use the small quantities of low-value or stranded resources that are widely available at a local scale. This includes flared natural gas, landfill gas, or wind power.

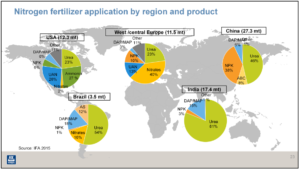

And they are market-flexible, meaning that they can serve various local needs, selling products like fertilizer, energy storage, or fuel; or services like resource independence, price stability, or supply chain robustness.

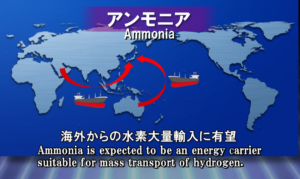

While the scale of these plants is small, the impact of this technology is big. As industry-insider publication Nitrogen+Syngas explained in its last issue, "as ammonia production moves toward more sustainable and renewable feedstocks the ammonia market is facing a potentially radical change."