Electrolysis

We’re as Strong as the Weakest Link: Building Scale through Value Chain Collaboration

Brazil’s first electrolysis-based ammonia plant takes shape

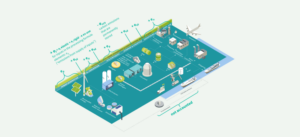

Brazil’s largest fertiliser producer Unigel has launched the country’s first industrial-scale electrolytic hydrogen & ammonia project. 60 MW of grid-connected, thyssenkrupp nucera electrolysers will feed the production 60,000 tonnes per year of ammonia. An existing ammonia production plant in Camaçari, Bahia province will provide the foundation for the project, which seeks to leverage the high share of renewable electricity in Brazil’s national grid. In other South American news, Uruguay’s officially-released Green Hydrogen Roadmap sets out ambitious decarbonisation goals. Green ammonia has a role both as an export commodity and for domestic use.

Introducing our Australia conference, meet our first panel

This year marks the fourth edition of our annual Australia conference, and we begin our event with a challenging topic - for good reason. As momentum grows, so do the stakes. The opportunity for hydrogen & ammonia in Australia is unparalleled, but establishing a world-leading industry requires many, many pieces to come together. To explore the challenges immediately ahead, we’ve brought together three familiar faces with a wealth of experience: Paul Hodgson (Scaling Green Hydrogen CRC), Alana Barlow (Sumitomo Australia) and Laurentiu Zamfirescu (Principal Safety and Risk Engineer, AMOG Consulting). Join us in-person or online, and make sure to register by the end of this week (Friday 29 July) to secure the early-bird rate.

Skovgaard renewable ammonia project orders electrolysers from Nel

The consortium developing the Skovgaard ammonia project has ordered an alkaline electrolyser system from Nel, bringing the 10 MW plant a step closer to reality. Skovgaard will be an important test case for hydrogen production directly from renewable energy, with no battery storage or firming to be used.

In other electrolyser news, German-based Sunfire and US-based Electric Hydrogen have received new funding to develop their technologies. Also in Germany, Siemens and Air Liquide will join forces to develop a GW-sized factory in Berlin, with 3 GW of PEM electrolyser units to be manufactured annually by 2025.

Harnessing opportunities for deep decarbonisation in India: new report

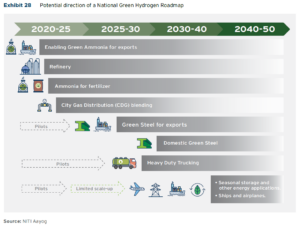

A new report from Indian government think-tank NITI Aayog and the Rocky Mountain Institute has outlined the enormous opportunity for India to produce renewable hydrogen & ammonia. Ammonia establishes itself early as a key part of this transition: both via the use of renewable hydrogen for fertiliser production, and as a near-term export vector. The report envisions 160 GW of installed electrolysers by 2030, of which nearly 100 GW could be dedicated to producing ammonia. This would make India one of the world’s largest producers of renewable ammonia for export by the end of the decade.

Nuclear-powered ammonia production

The potential for nuclear-powered ammonia production is developing fast. Two seperate industrial consortia (Copenhagen Atomics, Alfa Larval & Topsoe, and KBR & Terrestrial Energy) have formed to develop thorium-fueled reactors, and hydrogen & ammonia production is a key part of their plans. Given nuclear electricity dominates France’s energy mix, a grid-connected electrolyser project at Borealis’ fertiliser production plant in Ottmarsheim, France will be one of the first examples of commercial-scale, nuclear-powered ammonia production. And, while capital costs & lead times remain significant, mass production of new technologies and research into flexible power production capabilities are emerging as key to unlocking nuclear-powered ammonia production.

EU policy developments: CBAM & rules for emissions accounting

MEPs have voted to alter the scope of the upcoming Carbon Border Adjustment Mechanism (CBAM) to include hydrogen & ammonia, and for the scheme to cover indirect emissions from manufacture. Meanwhile, two Delegated Acts have established a starting point for rules governing the production of alternative fuels from electrolytic hydrogen, including definitions of “fully renewable” hydrogen and a comprehensive emissions accounting calculation. The European Commission will work with key stakeholders to further clarify and improve the new rules.

Topsøe planning new electrolyser manufacturing plant

Herning, Denmark will be the location for Haldor Topsøe’s new electrolyser manufacturing facility. The new facility will have an annual production capacity of 500 MW-worth of solid-oxide electrolyser units, scaling up to 5 GW. Topsøe’s announcement is the latest in a series of recent news items, suggesting that the momentum for electrolyser scale-up is building.

LSB Industries: renewable ammonia in Oklahoma

LSB Industries will partner with thyssenkrupp and Bloom Energy to develop renewable ammonia production at its existing facility in Pryor, Oklahoma. 30 MW of electrolysers will feed the production of 30,000 tonnes of renewable ammonia per year, with two electrolyser technologies (solid-oxide and alkaline) working side-by-side.