The Korean New Deal and ammonia energy

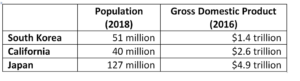

South Korea has featured in many Ammonia Energy news updates, but often in a scatter gun fashion that lacked the momentum of ammonia energy announcements coming from the other side of the Korea Strait. Now, South Korea is ready to step out from Japan’s shadow as a clean energy innovator and deployer in its own right. We’re seeing the beginnings of a well-articulated strategy to achieve society-wide decarbonisation in South Korea, with a starring role for clean hydrogen and clean ammonia.