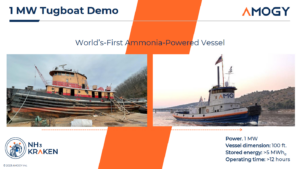

The NH3 Kraken: Amogy’s ammonia-powered tugboat

As part of our Maritime Ammonia Insights series, we explore progress onboard the NH3 Kraken, Amogy’s ammonia-powered tug being developed in New York state. We heard updates on vessel retrofits, design points, project partners, the ongoing relationship with the US Coast Guard, HAZOP assessments, regulatory work and the remaining challenges before the tug hits the water for operational trials. Amogy’s Abigail Jablanksky and Chief Safety Solutions’ Herbert Fowlkes joined Conor Furstenberg Stott in conversation.