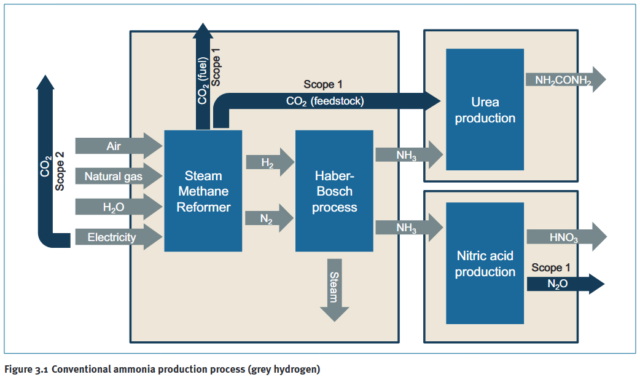

Decarbonizing existing, SMR-based ammonia plants: workshop recap

Decarbonization of existing steam methane reforming-based ammonia plants is possible, and changes in gas and heat flows can be recovered via alternative technologies. Recap our workshop in Atlanta, where we discussed the use of upstream methane monitoring equipment, electrolysers, carbon capture, hydrogen burners, energy storage and electric heating to achieve decarbonization of conventional ammonia plants.