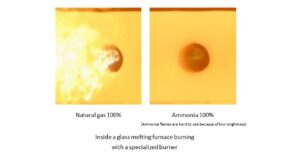

Asahi Glass Corporation announced it has successfully used 100% ammonia fuel to produce architectural glass over two days of testing at its Yokohama Technical Center, with NOx emissions below environmental thresholds. The news follows successful ammonia co-firing tests to produce cement clinker by Mitsubishi UBE Cement Corporation.

NOx Emissions

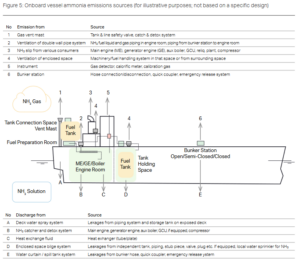

Maritime ammonia: fuel delivery, emissions mitigation systems near readiness

This week, we explore three new onboard systems: the Mitsubishi Ammonia Supply and Safety System (MAmmoSS®), Singapore-based C-LNG Solutions’ new ammonia low flash point fuel supply system, and a new NOx emission mitigation system developed by Korea Shipbuilding & Offshore Engineering and Hyundai Heavy Industries.

Creating Ammonia Value Chain for the Smooth Transition toward Carbon Neutrality

NoGAPS vessel project enters next phase

The second phase of the NoGAPS project is well underway. Led by the Maersk Mc-Kinney Møller Center for Zero Carbon Shipping, a detailed plan for the design, operation and business case for the future MS NoGAPS vessel will be developed. Construction and delivery is expected in 2024-25. Also in Scandinavia, Viridis Bulk Carriers has been awarded AiP from Bureau Veritas for its ammonia-fueled, short-sea, bulk carrier design.

Mitigating emissions risks from ammonia-powered vessels

Technology solutions to manage emissions from ammonia-powered internal combustion engines will be commercially available on a similar timeline to the engines themselves, a new report from the Mærsk Mc-Kinney Møller Center concludes. Although the authors are confident ammonia combustion emissions (including the potent greenhouse molecule N2O) will be successfully minimised, key gaps include a lack of industry-wide emissions thresholds and a poor understanding of the well-to-tank emissions of ammonia fuel, particularly CCS-based ammonia.

Quantifying the environmental impacts of ammonia at sea

In our latest episode of Maritime Ammonia Insights, we explored the findings of a new, landmark environmental study: Ammonia at Sea. Speakers representing the report’s co-authors joined us to discuss the results, what further work is required and how the report is being incorporated into policy discussions at the IMO.

Ammonia at Sea: exploring the potential impact on marine ecosystems

Hear more from the authors of the Ammonia at Sea report: an analysis of everything currently known about ammonia’s behaviour in the aquatic environment, plus the potential impacts of the use of ammonia as a marine fuel.

WinGD, CMB to develop & deploy ammonia-powered maritime engines

WinGD and CMB.TECH will team up to develop & deploy ammonia-fueled, two-stroke engines in ten Capesize bulk carriers, to be built at the Beihai shipyard in China. The pair will continue development of WinGD’s dual fuel X72DF design, which was first announced in December 2021. Delivery of the vessels is due in 2025-6.

Mitsubishi Heavy Industries to explore ammonia-fired gas turbines in Singapore, Indonesia

MHI, Keppel Infrastructure and DNV have agreed to explore the feasibility and deployment of a 100% ammonia-fired gas turbine on Jurong Island, Singapore. In Indonesia, MHI and Bandung Institute of Technology will work together to demonstrate 100% ammonia firing with MHI’s H-25 Series, 40 MW gas turbine.